Difference between revisions of "Laser Cutter"

From

(→Software) |

(→tutorial) |

||

| Line 84: | Line 84: | ||

===Burn=== | ===Burn=== | ||

| − | = | + | =Tutorial= |

| + | De aanstuurelectronica is aangepast met [[MKS_SBASE_Smoothie|Smoothie board]] voor instructies met Visicut lees instructie van [https://wiki.fablab.berlin/Laser_Cutting_Introduction_(Epilog) FabLab Berlijn] | ||

| + | |||

| + | Oude instructie met chineese software | ||

| + | |||

let op, scaling is nog niet goed en rondjes van een paar mm ook niet | let op, scaling is nog niet goed en rondjes van een paar mm ook niet | ||

| Line 118: | Line 122: | ||

Wacht totdat hij klaar is. Let er op dat het materiaal niet gaat vlammen. | Wacht totdat hij klaar is. Let er op dat het materiaal niet gaat vlammen. | ||

Stel het vermogen in op 0%, nu mag de klep open | Stel het vermogen in op 0%, nu mag de klep open | ||

| − | |||

=Software= | =Software= | ||

Revision as of 19:14, 27 April 2016

Contents

Usage

Don't use the following materials :

- MDF,

- PVC plastic of other material containing chlorine,

- Teflon or other materials containing fluorine,

- Rubber,

- Not recommended Polycarbonate (also known as Lexan, it produces a ugly edge and smokes like crazy).

If you are not sure you can use this diagram to identify the material

ALWAYS keep an eye on your job when the laser is working. Don't leave it unattended.

After each use clean the laser (lens and mirror) with a cotton swab and aceton, do not exert pressure on the lens while cleaning.

Steps

Turn on the laser

Switch on the wall & emergency button on the laser.

Put in the material

The table have to be on the right height, on the right there is a red line, the top of the material should align to this red line.

Check settings

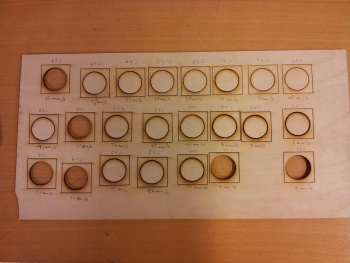

Find the right settings of the material you want to use.

CHECK table with settings (power and speed)

| Laser Draw | |||

|---|---|---|---|

| Material | Speed | Power | Number of times |

| Poplars plywood (populieren triplex) 3.5mm | ?? | ?? | ?? |

| Birch plywood 6mm | 5mm/s | 80% | 1x |

| Acrylic, black 2mm | ?? | ?? | ?? |

| Acrylic,transparent 2mm | ?? | ?? | ?? |

| Acrylic, transparent 3mm | ?? | ?? | ?? |

| Acrylic, transparent 4mm | ?? | ?? | ?? |

| Corel Draw (the lower the mm/s, the faster) | |||

|---|---|---|---|

| Material | Speed | Power | Number of times |

| Poplars plywood (populieren triplex) 3.5mm | 5mm/s | 90% | 2x |

Burn

Tutorial

De aanstuurelectronica is aangepast met Smoothie board voor instructies met Visicut lees instructie van FabLab Berlijn

Oude instructie met chineese software

let op, scaling is nog niet goed en rondjes van een paar mm ook niet

selecteer alles in inscape en druk op path->object to path sla in inscape je bestand op naar EMF op de nas In windows \\bark\laser In linux smb://bark/laser/ Je krijgt een schermpje te zien met wat instellingen Selecteer als basiseenheid: mm

start corelLaser, dit duurt even. Blijf geduldig wachten. verander papierformaat van A4 naar Tkkrlab laser (links boven) file -> import zoek op de Z schijf je EMF stel de units in op metric en controleer de size klik op een random locatie op je "papier" selecteer alle lijnen wat je wilt cutten druk op "cutting" (de knop lijkt op een sleutelhanger. Helemaal rechts boven aan het scherm) Je krijgt nu de engraving manager te zien

verplaats je object naar de plek waar je wilt cutten Je kan de Common parameters aanpassen als je wilt Wil je 1 keer cutten. Zorg dan dat repeat op 1 times staat! Als je bijvoorbeeld twee keer hetzelfde wilt cutten op de zelfde plek, stel dan "repeat" in. Je kan bij de style de snij volgorde instellen. Standaard staat dit op "As drawing" Kijk voor de speed in de materialenlijst

leg je matteriaal in de lasercutter. Zorg ervoor dat het rode streepje aan de zijkant op dezelfde hoogte is als de bovenkant van je object Doe de klep nu dicht! stel het vermogen in op de lasercutter (zie materialenlijst) druk op start in de engraving manager De lasercutter gaat nu cutten Wacht totdat hij klaar is. Let er op dat het materiaal niet gaat vlammen. Stel het vermogen in op 0%, nu mag de klep open

Software

LaserDRW

This program is mainly for engraving and limited in the functions.

There is no eps / svg import but you can read windows EMF files.

- The program can be set to engrave or marking ( for nice pictures ) or cutting ( for nice parts).

- When cutting working from vectors is advised as it will be a lot faster.

- Engraving can be done from bitmaps (jpg, png, bmp...) be advised that the lighter the wood, the better the results will look like.

CorelDraw

- you can cut with the laser plugin.

- support almost all bitmap and vector file types (warning for svg: not the same dpi as inkscape)

- https://www.youtube.com/watch?v=MR7967VHKnI tutorial

Inkscape

There is no direct support to use this laser with inkscape, but there is a workaround. You can save to windows .emf file (on mac and windows), this format can be read with LaserDRW. HOWEVER:

- Using a line width of < 0.13 mm in your designs will result in some of your cutting lines dashed. Using a line width > 0.13 will make the cutter cut all your lines twice. Pick your poison.

Notes:

- all the paths made in the inkscape file will be followed, so even if you used masks or other things, it is NOT WISIWIG!

- you can only save to .emf in inkscape in windows. (for linux, you can use the .wmf format, tested)

- works great what to do to make it work, get the latest version from the inkscape websited, the one in the repo's is way to old and doesn't support saving as .emf

- if installed open inkscape make your design save it as .emf, be sure to tick the boxs saying: Convert dashed/dotted lines to single lines.

- make sure that your design has the stroke set to 0.001 mm or else it will do double cute edges.

- and your good to go!

Import in laserDRW:

- Open your file with LaserDRW - Check the dimensions - Open the "engrave" dialog - Choose the "cutting" strategy instead of the default "engrave" if you want to cut - Selecting "nearest" will make the laser follow a path that is not utterly insane - I suggest to use a non null "fill the gaps" (I use 0.1 mm) to minimize unecessary movements - Once ready, check you have put your material to cut and click "starting". - Check the tray icon notifications, it can take long to export your paths if you have a lot of curves. Up to a few minutes. It will start eventually. - Enjoy the smell.

Specifications

- Item Code: CW3040

- Working Table Size: 300 *400mm

- Laser Tube : CO2 glass Tube

- Laser Power : 40W

- Cutting Speed : 0-2000 mm/min

- Engraving Speed : 0-3000mm/min

- Resolution : ±0.05mm /1000DPI

- Support Fils : BMP,HPGL,PLT,DST and AI

- Port : USB 2.0 Plug and play

- Software : CorelDraw (Direct Output)

- Motor : Stepper

- Power Voltage : AC 110-220V±10%,50-60Hz

- Working Environment : 0-45? 5-95% (humidity)

- Power consumption : 300W (Total)

- Software compatible : CorelDraw,AutoCAD,Photoshop

- Table type : Honeycomb /Blade type/Aluminum (Optional upon needs)

- Position system :RED dot pointer

- Coolingmode : Water-cooled system

- Cutting thickness : 3-4mm (upon materials type)

- Rotary device : optional

- Packing Size : 123*79*60cm

- Gross Weight : 77/kg

Controller board

- Lihuiyu Studio 6C6879-LASER-M2:6 board from http://www.3wcad.com/

- Firmware : 2015.02.15

Included Software

- LaserDRW

- Corel Draw driver (you need Corel Draw, this is NOT included)

External Links

If you want to improve the laser check the following links

Box makers

Usage Settings

Future improvements

- Replace control board with laos https://tuxic.nl/webshop

Maintenance

Clean the lens and mirror after each job or at least once a day. Use cotton stick with aceton and lightly brush the surface of the mirror/lens.

Keep the rods oiled (no WD-40)

I (Duality) Quote:

Never use wd-40 as a lubricant. The primary ingredients in wd-40 are kerosene and mineral spirits, which can be corrosive and are otherwise not suitable for mechanical lubrication.

Also you don´t want a (wd-40) sprayed mirror ;).

Issues

there is some ghosting in the laser, a link i found suggests that it's the laser not hitting the lens right in the head due to the mirror in the head being misaligned. forum

or as the forum also suggests a cracked lens could be the cause.

Dubliner, I had the same problem on my Vytek. It's all in the alignment and the point where the beam passes through the nozzle below the focus lens. The beam (on mine) was grazing the nozzle and reflecting off. It takes a VERY in-depth alignment procedure to correct this. Take your time, bring a lunch. Wish I'd bought a Multicam.

focusing: link

how to maintain a laser cutter: maintenance

Water Cooling

If you need to replace the water in the water cooling replace it with Demi water with 10% antivries (in case the room can get < 0c).

Air Filter

- Transport keep it upright (or let it rest 96 hours).

Replacement parts

- Laser tube around € 500 (should last between 4000 hours (if you use always full power) - 10000 hours (if you only use engraving).

- Replacement Air filter : cost € 85 for active carbon, € 200 for the rest (285 of the whole filter)). Expected life 2 years

- Mirror € 80,=

- Lens 38 mm € 250,=