Difference between revisions of "Cnc machine"

From

(→Leveling the base) |

(→Leveling the base) |

||

| Line 17: | Line 17: | ||

== Leveling the base == | == Leveling the base == | ||

| − | Leveling of our pexiglass plate took 3 hours. We needed to add some aircooling to prevent melting the plastic. That happened during several tries before. The final result worked out quite well. | + | Leveling of our pexiglass plate took 3 hours. We needed to add some aircooling to prevent melting the plastic. That happened during several tries before. The final result worked out quite well.<br> |

[[File:start-leveling.jpg|border|x200px]] | [[File:start-leveling.jpg|border|x200px]] | ||

[[File:owls-watching.jpg|border|x200px]] | [[File:owls-watching.jpg|border|x200px]] | ||

Revision as of 16:36, 30 July 2014

| Project: cnc machine | |

|---|---|

| 360x360px | |

| Name | cnc machine |

| Initiator | tkkrlab |

| Status | Actief |

| Skills | {{{Skillz}}} |

| Summary | bouw van cnc machine voor TkkrLab |

Contents

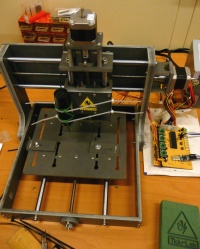

Zen CNC

After some searching, debating and comparison we have decided to spend our 500 Euro budget on the Zen toolworks 7x7 CNC.

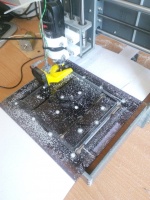

our machine with test setup:

PDF Manual or wiki

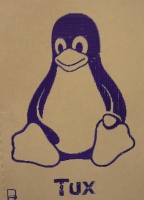

First tests with pen and 1mm drill as cutting tool:

.

. .

.

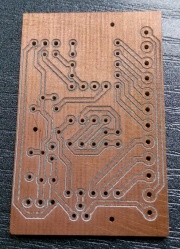

First Actual PCB drilling:

Leveling the base

Leveling of our pexiglass plate took 3 hours. We needed to add some aircooling to prevent melting the plastic. That happened during several tries before. The final result worked out quite well.

Some testing and milling with our new spindle

Who

Goal

- CNC machine voor minstens XY as

- minder dan 500 Euro aan onderdelen

- kop: Dremel boor of extrudeer machine monteerbaar

- suitable for PCB-milling

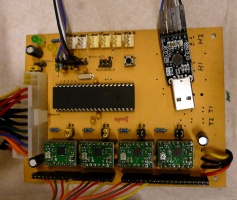

Electronics

From many electronics options we have chosen to make reprap Generation 7 Electronics. It can drive 4 stepper motors (XYZ and one Extruder), is easy to build, uses common pololu stepper drivers and has many options including electronics for contolling heaters, endstops etc.

The finished electronics (parts for 3D printer left out):

Firmware

Currently we are testing with Teacup Firmware which is supposed to also work for CNC-milling. but the firmware lacks Arc support in Gcode so we might have to switch to Marlin or grbl.

- In the mean time we modified the Teacup firmware so it now supports arcs :)

Cad / Cam and other software

We are testing some software for different purposes:

- Printrun, a utility to control steppers manualy and send gcode to machine

- ReplicatorG, an open source 3D printing program, also with gui to controll the steppers manualy

- GcodeTools plugin for Inkscape so we can use inkscape designs

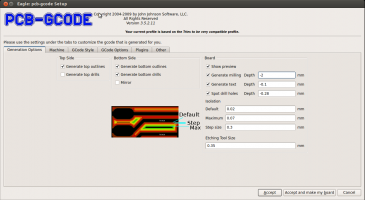

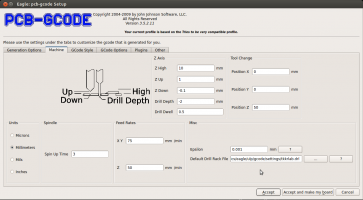

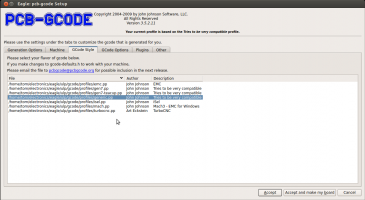

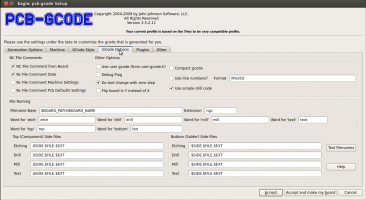

- pcb-gcode plugin for Eagle for use with pcb milling

Free 3D Modeling Software

- Google SketchUp (requires the freeware plugin to export STL)

- Blender (GPL)

- Art of Illusion (GPL)

- TopMod3D (GPL)

- Wings3D (GPL)

- StructureSynth (GPL)

- OpenSCAD (GPL)

- Heekscad

- FreeCAD

Add ons / Wishlist

List of add ons and options for use with the CNC

- dremel flex shaft mount Peter has designed and printed a similar set of mounts but the flexible dremel shaft was a little bit too flexible. A new design was made and printed by Peter so the dremel is now mounted at the CNC directly.

- Proxxcon IBS/E precision milling tool suitable for SMD pcb milling (hier voor 90 Euro)

- adapter om de IBS/E op de zen toolworks te monteren

(short) PCB milling instructions using eagle with gcode with the TkkrLab CNC

- Make sure the lower left corner of your board is at coaordinates x=0.0, y=0.0

- If you have a double sided board draw a hole of 1.0mm at x0, y0. This helps to allign the board after swapping sides.

- If you want to cut out the board from the pcb after milling and drilling draw some 'wires' around your board in the milling layer (46). The with of the wires should the same with of the milling bit used to cut out the board (2mm is available for this at the moment). The dimention should be your PCB outline + radius of your milling bit.

- Check your board (DRC) with design rules file for eagle: File:Tkkrlab-CNC.zip

- Use the following settings in the first 4 tabs from the gcode plugin settings in eagle:

- when all is done split your bottom.drill file in seperate files for drill diameters 0,7mm 0,8mm and 1.0mm. Everything larger then 1.0mm should also be drilled with 1.0mm and can be manually drilled with a larger bit after your board is finished.

- Place your PCB material against the x-axis and set your home (0.0) position on the lower left on the pcb. If you cut out your board afterwards leave enough room for the mill bit you use for that

- Put a piece of scratch (but evenly thick) wood under your board so you not cut or drill into the bottom plate.

- for single side boards: bottom milling and after that use your splitted drill files to drill the holes using the correct drill bit for each file.

- for double sided boards: First drill a 1mm hole at 0.0. Then start top milling, wait until ready and then turn around your board and place it again agains the x-axis. Allign your board using your drilled hole and home the CNC to that. Start milling the bottom layer and finaly use your splitted drill files to drill the holes using the correct drill bit for each file.

- end cut out milling: Make sure the cnc is still aware of the correct coordinates (go to 0.0 and check if it at correct). Place the miling bit, home the Z axis and use the bott.mill file to cut out our board. (press the board down a bit when its almost finished and becomes loose).