Difference between revisions of "SpaceState ESP"

From

| Line 1: | Line 1: | ||

{{Project | {{Project | ||

| − | |ProjectName=SpaceState | + | |ProjectName=SpaceState nodeMCU ESP8266 Clock |

|Owner=zeno4ever | |Owner=zeno4ever | ||

| − | |Status= | + | |Status=100% |

|Skillz=Basic Electronics, Arduino Software (C) | |Skillz=Basic Electronics, Arduino Software (C) | ||

|Summary=Show space open/close state with nodeMCU / ESP-12E / ESP8266 | |Summary=Show space open/close state with nodeMCU / ESP-12E / ESP8266 | ||

| Line 26: | Line 26: | ||

* source code for nodeMCU : https://github.com/zeno4ever/spacestatus_ESP | * source code for nodeMCU : https://github.com/zeno4ever/spacestatus_ESP | ||

* Library for json processing https://bblanchon.github.io/ArduinoJson/ | * Library for json processing https://bblanchon.github.io/ArduinoJson/ | ||

| − | * Arduino IDE for uploading source to nodeMCU | + | * [https://www.arduino.cc/en/Main/Software Arduino IDE] for uploading source to nodeMCU |

=Steps= | =Steps= | ||

| Line 45: | Line 45: | ||

===LED remarks=== | ===LED remarks=== | ||

| − | If you order a LED chip check what type you buy, you have commen anode and commen cathode types. These have to be connected different I | + | If you order a LED chip check what type you buy, you have commen anode and commen cathode types. These have to be connected different I used an common anode. I include setting you can change. I have no tested this part so there may more changes needed to make this work. |

I also use one resistor since i only show one color all times. If you want to use more then one color at a time then you should use a resistor per color, so 3 for R,G,B. | I also use one resistor since i only show one color all times. If you want to use more then one color at a time then you should use a resistor per color, so 3 for R,G,B. | ||

| − | You can cut a part of the LED as long you | + | You can cut a part of the LED as long you don't touch the parts where the electronics are. For me I 'decapped' the LED with a iron saw and sanding it down to have a flat surface. |

Latest revision as of 18:24, 9 April 2017

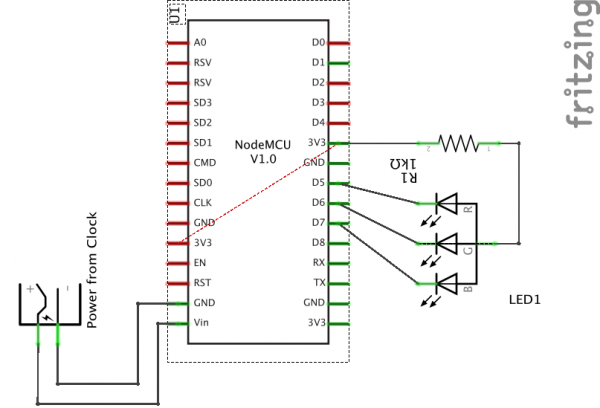

I wanted to see if the TkkrLab hackerspace is open on my clock. For this I used an nodeMCU with a RGB led to request the spaceapi every 10 mins and display open (green) or closed (red) status. The nodeMCU is a developer board with an ESP8266 / ESP12-E chip. There are a few different types of nodemcu's, check out this article for more information about these

Resources

Parts List

- Clock

- nodeMCU v2

- diffuse 10 mm RGB LED

- 1x 1K resistor (you can alter this depending how brite the LED should be)

Software

- source code for nodeMCU : https://github.com/zeno4ever/spacestatus_ESP

- Library for json processing https://bblanchon.github.io/ArduinoJson/

- Arduino IDE for uploading source to nodeMCU

Steps

I used male breadboard connectors to connect everything to the nodeMCU, you can solder the RGB led directly on the wire (with one resistor on the anode (+))

The clock I have has a 6v that is connected to the Vin and GND of the nodeMCU

- Check the clock you want to use if there is enough space inside to put nodeMCU inside and where to place the LED.

- Check if you can use the power of the clock and this is good for Vin. In my case i had 6 V, this in within the range of 4.5V ~ 9V. If you have a other version of nodeMCU check the documentation.

- Download the source and change the settings for your hackerspace.

- Upload code to nodeMCU via USB

- Connect the RGB LED and power in the the nodeMCU

LED remarks

If you order a LED chip check what type you buy, you have commen anode and commen cathode types. These have to be connected different I used an common anode. I include setting you can change. I have no tested this part so there may more changes needed to make this work.

I also use one resistor since i only show one color all times. If you want to use more then one color at a time then you should use a resistor per color, so 3 for R,G,B.

You can cut a part of the LED as long you don't touch the parts where the electronics are. For me I 'decapped' the LED with a iron saw and sanding it down to have a flat surface.